03

2025

-

07

Understanding Angular Contact Ball Bearings: A Comprehensive Guide to Performance and Precision

Understanding Angular Contact Ball Bearings: A Comprehensive Guide to Performance and Precision Table of Contents 1. Introduction to Angular Contact Ball Bearings 2. Design and Structure of Angular Contact Ball Bearings 3. Operational Principles and Load Capacity 4. Applications of Angular Contact Ball Bearings 5. Maintenance Practices for Enhanced Longevity 6. Common Issu

Understanding Angular Contact Ball Bearings: A Comprehensive Guide to Performance and Precision

Table of Contents

- 1. Introduction to Angular Contact Ball Bearings

- 2. Design and Structure of Angular Contact Ball Bearings

- 3. Operational Principles and Load Capacity

- 4. Applications of Angular Contact Ball Bearings

- 5. Maintenance Practices for Enhanced Longevity

- 6. Common Issues and Faults in Angular Contact Ball Bearings

- 7. Advantages and Disadvantages of Angular Contact Ball Bearings

- 8. Conclusion

- 9. Frequently Asked Questions

1. Introduction to Angular Contact Ball Bearings

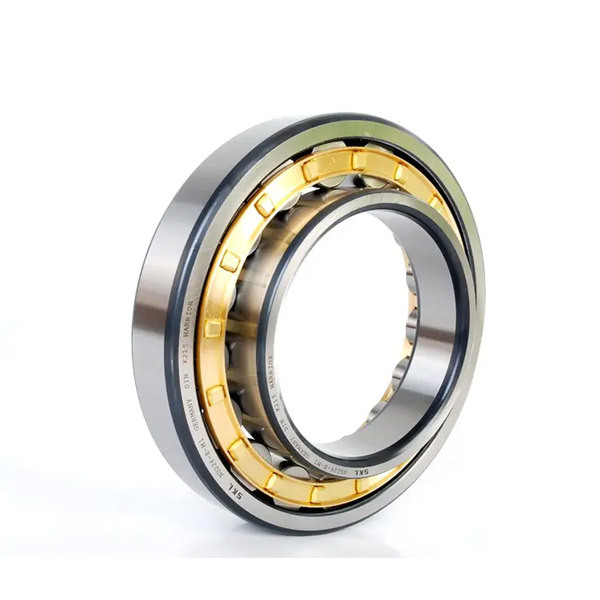

Angular contact ball bearings are specialized components designed to handle both axial and radial loads. This unique capability makes them a crucial choice in various high-speed applications. Their design enables them to maintain a higher load capacity than standard ball bearings. The angle of contact determines their performance and efficiency, making it essential to understand their specifications for optimal application.

2. Design and Structure of Angular Contact Ball Bearings

Angular contact ball bearings consist of an inner ring, an outer ring, and a set of balls. The key feature of their design is the angle at which the balls contact the races. This angle allows the bearings to support loads from various directions. The following aspects detail their structure:

2.1 Inner and Outer Rings

Both the inner and outer rings are designed with grooves that accommodate the balls. The contact angle between the balls and the rings can vary, typically ranging from 15 to 40 degrees, which significantly affects the bearing's load capacity.

2.2 Balls

The balls are often made from high-carbon chrome steel or ceramic to ensure durability and resistance to wear. The size and number of balls are also crucial, as they influence the overall load capacity of the bearing.

2.3 Raceways

The raceways are precision-machined to provide a smooth surface for the balls to roll against, minimizing friction and wear over time. The quality of raceway machining directly impacts the performance and longevity of the bearing.

3. Operational Principles and Load Capacity

Angular contact ball bearings operate on the principle of maintaining alignment between the balls and the raceways during operation. The following points elucidate their operational capabilities:

3.1 Load Distribution

The design allows for efficient load distribution across the bearing. When subjected to axial loads, the contact angle plays a pivotal role in determining how the load is handled. A higher contact angle typically allows for greater axial load capacity.

3.2 Speed Capabilities

Angular contact ball bearings are designed for high-speed applications. Their design minimizes frictional losses, permitting smoother and faster operation without overheating.

3.3 Multiple Bearing Arrangements

These bearings can be configured in various arrangements, such as back-to-back or face-to-face, to enhance load handling capabilities and improve stability in applications involving high axial loads.

4. Applications of Angular Contact Ball Bearings

Due to their unique characteristics, angular contact ball bearings find applications in a myriad of industries, including:

4.1 Aerospace

In aerospace applications, reliability and performance are paramount. Angular contact ball bearings are employed in engines, landing gear, and other critical components.

4.2 Automotive

They are used in automotive wheel hubs, transmissions, and steering systems, providing the necessary strength and precision for effective vehicle performance.

4.3 Industrial Machinery

In industrial settings, these bearings support high-speed spindles in machine tools, conveyors, and robotics, allowing for enhanced operational efficiency.

4.4 Electrical Engineering

In electric motors and generators, angular contact ball bearings help maintain stability and precision, ensuring smooth operation under varying load conditions.

5. Maintenance Practices for Enhanced Longevity

To maximize the lifespan of angular contact ball bearings, adopting effective maintenance practices is crucial. The following strategies can aid in ensuring optimal performance:

5.1 Regular Inspection

Conducting routine inspections helps identify wear and potential issues early. Look for signs of rust, pitting, or abnormal noise during operation.

5.2 Proper Lubrication

Using the correct lubricant and ensuring it is replenished regularly can significantly reduce friction and wear. Selecting the appropriate grease or oil based on the operating environment is vital.

5.3 Vibration Monitoring

Implementing vibration monitoring techniques can provide insights into the bearing's condition. Anomalies in vibrational patterns can signal underlying issues that require attention.

5.4 Cleaning Procedures

Keeping bearings clean from contaminants is essential. Dust and debris can lead to premature wear. Employ appropriate cleaning methods when servicing bearings.

6. Common Issues and Faults in Angular Contact Ball Bearings

Understanding common problems faced by angular contact ball bearings can facilitate preventive measures. Here are some frequent issues:

6.1 Misalignment

Improper installation can lead to misalignment, resulting in uneven wear and reduced bearing life. Ensuring precise alignment during installation is critical.

6.2 Contamination

Ingress of dirt and moisture can deteriorate the bearing's performance. Using seals and shields can mitigate the risk of contamination.

6.3 Overloading

Exceeding the specified load limits can lead to premature failure. Always adhere to manufacturer recommendations regarding load capacities.

6.4 Temperature Fluctuations

Extreme temperatures can affect lubricant performance and bearing materials. Monitoring operating temperatures and using appropriate lubricants can help alleviate these issues.

7. Advantages and Disadvantages of Angular Contact Ball Bearings

Like any mechanical component, angular contact ball bearings come with their set of advantages and disadvantages:

7.1 Advantages

- High Load Capacity: They can handle significant axial and radial loads, making them suitable for demanding applications.

- High-Speed Capability: Their design allows for smoother operation at higher speeds.

- Versatile Configurations: They can be arranged in various configurations to meet specific application needs.

- Precision Engineering: Angular contact ball bearings provide excellent precision and stability in mechanical systems.

7.2 Disadvantages

- Cost: They tend to be more expensive than standard bearings due to their complex design and manufacturing.

- Installation Sensitivity: Proper installation is critical; misalignment can lead to rapid wear.

- Maintenance Requirements: Regular maintenance is necessary to ensure optimal performance and longevity.

8. Conclusion

Angular contact ball bearings are essential components in various applications, providing a robust solution for managing axial and radial loads. Understanding their design, operational principles, and maintenance needs can significantly enhance their performance and longevity. By adopting best practices in installation and maintenance, industries can leverage the full potential of these bearings, ensuring enhanced efficiency and reliability in their machinery.

9. Frequently Asked Questions

1. What is the primary function of angular contact ball bearings?

Angular contact ball bearings are designed to support both axial and radial loads, making them ideal for applications with complex load requirements.

2. How do I determine the correct contact angle for my application?

The contact angle depends on the specific load conditions. Generally, higher angles can handle greater axial loads, while lower angles are suited for applications where radial loads dominate.

3. What maintenance practices can extend the life of my angular contact ball bearings?

Regular inspections, proper lubrication, vibration monitoring, and keeping the bearings clean can significantly extend their lifespan.

4. Can angular contact ball bearings be used in high-temperature environments?

Yes, but it's essential to select appropriate lubricants and materials that can withstand extreme temperatures to prevent failure.

5. How can I tell if my angular contact ball bearings are failing?

Signs of failure include excessive noise, vibrations, discoloration, or overheating. Regular monitoring can help identify issues early.

10% DISCOUNT FOR NEW CUSTOMERS

WhatsApp:+8613211157555

Tel: +8613211157555

Address:Room 1106, 11th Floor, No. 23, Fengshan West Road, Jinbang Community, Daliang Street, Shunde District, Foshan City, Guangdong Province

Copyright 2025 Schaeffler (Guangdong) Transmission Technology Co., Ltd. SEO Business license