32972

Still hesitating? Get the samples first,Contact Us!

Classification

Product Description

32972 TS (Single Row Tapered Roller Bearings) (Metric) consist of a tapered inner ring assembly and an outer ring. 32972 bore dia is 360 mm. Its out dia is 480 mm. 32972 roller material is Roller_Material. Its seal type is Seal_Bearing. The 32972 TS (Single Row Tapered Roller Bearings) (Metric) can bear both radial and axial loads with ease and provides low friction during operation even under the most severe conditions.

Typical applications include

Gearing Systems and Transmissions, Thermal Power Coal Transporters, Port Equipment, Rubber and other Industrial applications, Machine Tool Spindles, Gear Reducer, Automotive Drive Axle, Aircraft wheels, Agricultural Wheels, Tensioning Roller, Raking Machine, Construction and Mining Equipment, Railroad Axle-box, etc.

General Selection Factors

Several factors must be considered for choosing tapered roller bearings. These factors include the roller material, design, shields and seals, cage, Annual Bearing Engineering Committee (ABEC) grade, radial clearance, and lubricant, etc.

| Part Number | 32972 |

| Cone Part Number | X32972M |

| Cup Part Number | Y32972M |

| System of Measurement | Metric |

| Type | Bearing |

| Bearing Type | Roller |

| Roller Bearing Type | Tapered |

| For Load Direction | Combined |

| Construction | Single Row |

| Seal Type | Open |

| Cups Type | Standard |

| Series | 32972M |

| Bore Dia | 360 mm |

| Bore Dia Tolerance | -0.04mm to 0 |

| Outer Dia | 480 mm |

| Outer Dia Tolerance | -0.045mm to 0 |

| Cone Width | 76 mm |

| Cone Width Tolerance | -0.25mm to 0 |

| Cup Width | 57 mm |

| Cup Width Tolerance | -0.3mm to 0 |

| Width | 76 mm |

| Width Tolerance | +0.4mm to -0.4mm |

| Cone Backface ToClear Radius | 4.06 mm |

| Cup Backface ToClear Radius | 3.05 mm |

| Cone Frontface Backing Diameter | 378 mm |

| Cone Backface Backing Diameter | 385 mm |

| Cup Frontface Backing Diameter | 466.1 mm |

| Cup Backface Backing Diameter | 451.1 mm |

| Cage Cone Frontface Clearance | 5.8 mm |

| Cage Cone Backface Clearance | 9.4 mm |

| Effective Center Location | 20.6 mm |

| Ring Material | Chrome Steel |

| Roller Material | Chrome Steel |

| Cage Material | Steel |

| Dynamic Radial Load | 281250 lbf |

| Static Radial Load | 625500 lbf |

| Dynamic Radial Rating(90 Million Revolutions)(C90) | 72900 lbf |

| Dynamic Thrust Rating(90 Million Revolutions)(Ca90) | 57150 lbf |

| Lubrication | Required |

| Temperature Range | -30° to 110 °C |

| ABEC Rating | ABEC-1 |

| Radial Clearance | Standard (Available in C3/C4/C5) |

| RoHS | Compliant |

| REACH | Compliant |

| Weight | 79.81 lb |

The design of these bearings also facilitates efficient lubrication and heat management. The tapered geometry helps channel lubricant (whether grease or oil) effectively across the rolling contact surfaces. The rolling action pumps lubricant through the bearing, ensuring all critical components are protected from wear and that heat is carried away. Many modern tapered roller bearings are also designed with advanced cage technologies that further optimize lubricant retention and distribution. This effective lubrication is vital for maintaining performance and achieving the long service life for which these bearings are renowned.

Manufacturing advancements have also enhanced their performance. Precision grinding of rollers and raceways ensures minimal operational noise and vibration. The use of case-hardened steel provides a hard, wear-resistant surface while maintaining a tough, shock-resistant core. Specialized designs, such as X-life classifications, offer increased load ratings and extended service life, pushing the boundaries of performance.

In conclusion, the tapered roller bearing is a masterpiece of mechanical design. Its unique ability to handle combined radial and axial loads, its inherent durability, its adjustable internal clearance, and its efficient lubrication make it an indispensable component across a vast spectrum of industries. From the family car to the massive haul truck at a mine site, the robust and versatile nature of the tapered roller bearing ensures the smooth, reliable, and efficient operation of the machinery that powers the modern world.

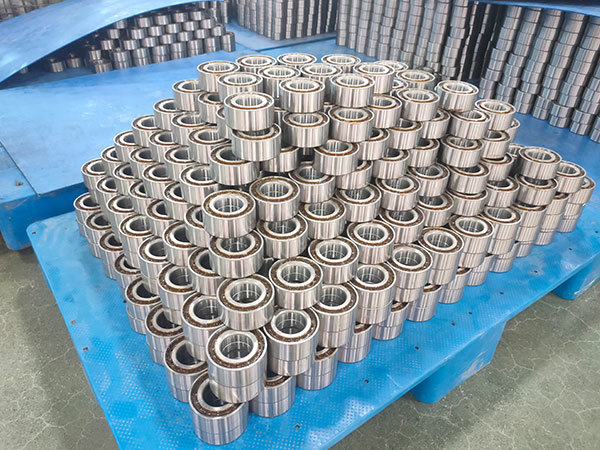

FACTORY APPEARANCE

We implement rigorous testing and quality control processes to ensure that every product meets the highest standards of durability and reliability.

PACKING AND DELIVERY

Intelligent warehouse management, efficient logistics connection, and extremely fast delivery without delay after placing an order.

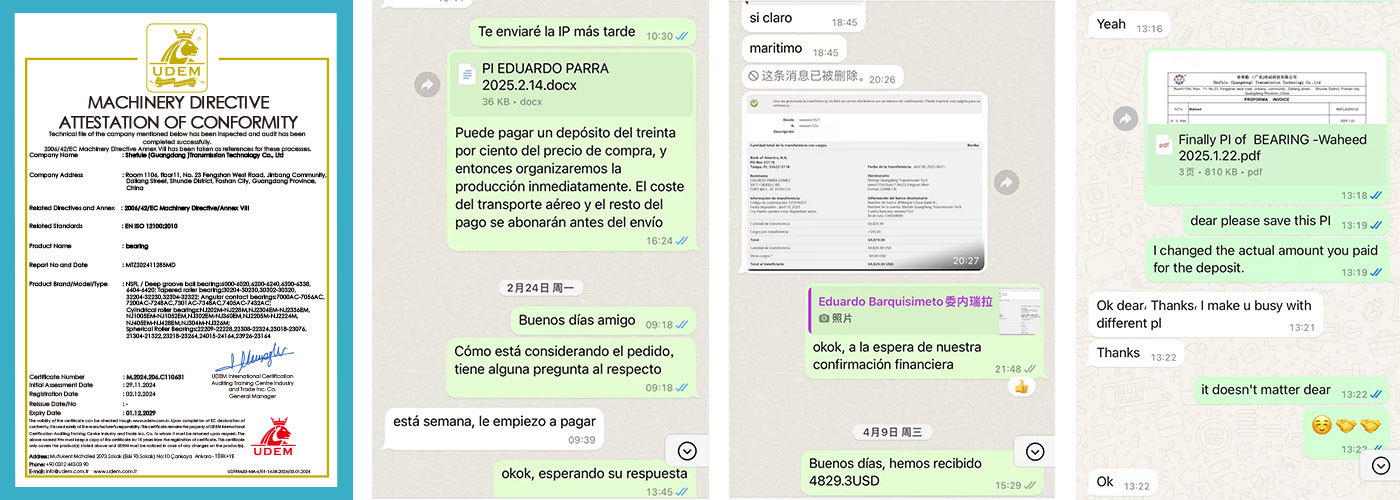

CUSTOMER CHAT

APPLICATION AREAS

We provide you with customized solutions for your industry.

CONTACT US

Provide you with free samples and quotes.

RELATED PRODUCTS

Experience the difference that our expertise and dedication can make for your business.

10% DISCOUNT FOR NEW CUSTOMERS

WhatsApp:+8613211157555

Tel: +8613211157555

Address:Room 1106, 11th Floor, No. 23, Fengshan West Road, Jinbang Community, Daliang Street, Shunde District, Foshan City, Guangdong Province

Copyright 2025 Schaeffler (Guangdong) Transmission Technology Co., Ltd. SEO Business license