2305 M

Still hesitating? Get the samples first,Contact Us!

Classification

Product Description

INTERCHANGE

The Bearing part series 2305 M is a potential replacement for these common bearing part numbers.

| MCMASTER | NSK | SKF |

| 6660K54 | 2305 | 2305 M |

Design Features of 2305 M Bearing

2305 M Bearing is a type of rolling-element bearing uniquely desi

gned to tolerate misalignment of the shaft with respect to the housing. It has two rows of balls and a common spherical raceway in the outer ring, allowing the bearing to be self-aligning. 2305 M bore dia is 25 mm. Its out dia is 62 mm. Its width is 24 mm. 2305 M Bearing is versatile and adaptive, ensuring smooth operation even when not perfectly aligned. Its unique design helps prevent stresses on the bearing, resulting in a longer operational life.

What Benefits Can 2305 M Bearing Provide?

Misalignment Adaptability: These bearings efficiently handle both static and dynamic misalignment, resembling the self-aligning capabilities of spherical roller bearings.

High-Speed Efficiency: With reduced friction compared to other bearings, they remain cool, even at elevated speeds.

Longevity and Low Maintenance: Their ability to run cooler means longer bearing life and fewer maintenance breaks.

Optimized for Light Loads: They operate exceptionally well, even under minimal load conditions.

Noise and Vibration Reduction: Ideal for applications like fans, these bearings help in decreasing noise and vibration levels.

What Can 2305 M Bearing Be Used for?

2305 M Bearing is suitable for applications where misalignment can arise from errors in mounting or from shaft deflection.

Automotive: Used in power steering systems, drive shafts, and steering column joints, where angular misalignments are common.

Agricultural: Essential in farm equipment like tractors and harvesters, where uneven terrains can cause shaft misalignment.

Textile: Deployed in spinning and weaving machines where smooth, consistent rotation is crucial.

Conveyor Systems: Useful in belt systems to maintain consistent belt tension and alignment, especially in long-distance conveyors.

Mining and Double Row: Used in crushers, vibrating screens, and heavy-duty machinery that undergo rigorous operation and potential shaft deflections.

| Part Number | 2305 M |

| System of Measurement | Metric |

| Bearing Type | Ball |

| For Load Direction | Radial |

| Construction | Double Row |

| Seal Type | Open |

| Chamfer Dimension | 1.1 mm |

| Bore Dia | 25 mm |

| Bore Dia Tolerance | -0.01mm to 0 |

| Outer Dia | 62 mm |

| Outer Dia Tolerance | -0.013mm to 0 |

| Width | 24 mm |

| Width Tolerance | -0.12mm to 0 |

| External Diameter On Inner Ring | 35.5 mm |

| Internal Diameter On Outer Ring | 50.6 mm |

| Dynamic Radial Load | 5445 lbf |

| Static Radial Load | 1474 lbf |

| Max Speed (X1000 rpm) | 16 |

| Ring Material | Chrome Steel |

| Ball Material | Chrome Steel |

| Cage Material | Nylon |

| Lubrication | Lubricated |

| Temperature Range | -30° to 110 °C |

| RoHS | Compliant |

| REACH | Compliant |

| Weight | 0.37 kg |

Self-aligning ball bearings are precision-engineered components designed to accommodate misalignment and reduce friction in rotating machinery, ensuring smooth operation and extended service life. These bearings feature a double-row arrangement of balls and a spherical outer ring raceway, enabling them to self-align and compensate for shaft deflection or mounting inaccuracies—making them ideal for applications where alignment challenges are common. Their robust yet flexible design makes them a preferred choice for industries such as agriculture, mining, automotive, and material handling, where reliability under demanding conditions is critical.

Constructed from high-quality chrome steel or stainless steel for corrosion resistance, self-aligning ball bearings are built to withstand heavy radial loads and moderate axial loads in both directions. The unique spherical outer ring design allows the inner ring and ball assembly to pivot, automatically adjusting to angular misalignment up to several degrees without increasing stress on the bearing. This self-aligning capability reduces wear, minimizes vibration, and prevents premature failure, even in applications with shaft bending or housing distortions.

These bearings are available in open, shielded, or sealed configurations to suit different environmental conditions. Open variants allow for easy lubrication and inspection, while shielded or sealed types retain grease and block contaminants, making them suitable for dusty or humid environments. Advanced lubrication options, including high-temperature or food-grade greases, further enhance performance in specialized applications such as food processing, paper mills, or chemical plants.

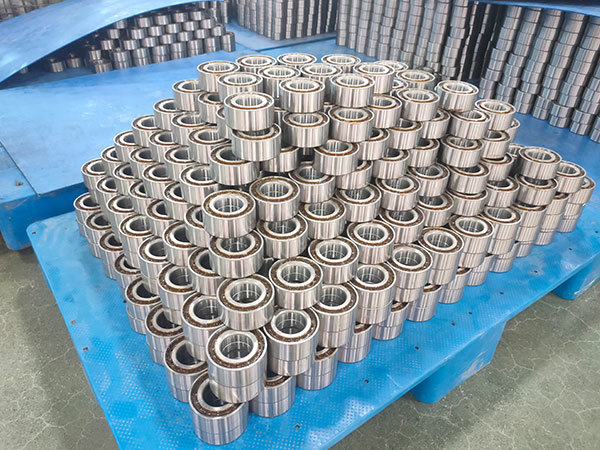

FACTORY APPEARANCE

We implement rigorous testing and quality control processes to ensure that every product meets the highest standards of durability and reliability.

PACKING AND DELIVERY

Intelligent warehouse management, efficient logistics connection, and extremely fast delivery without delay after placing an order.

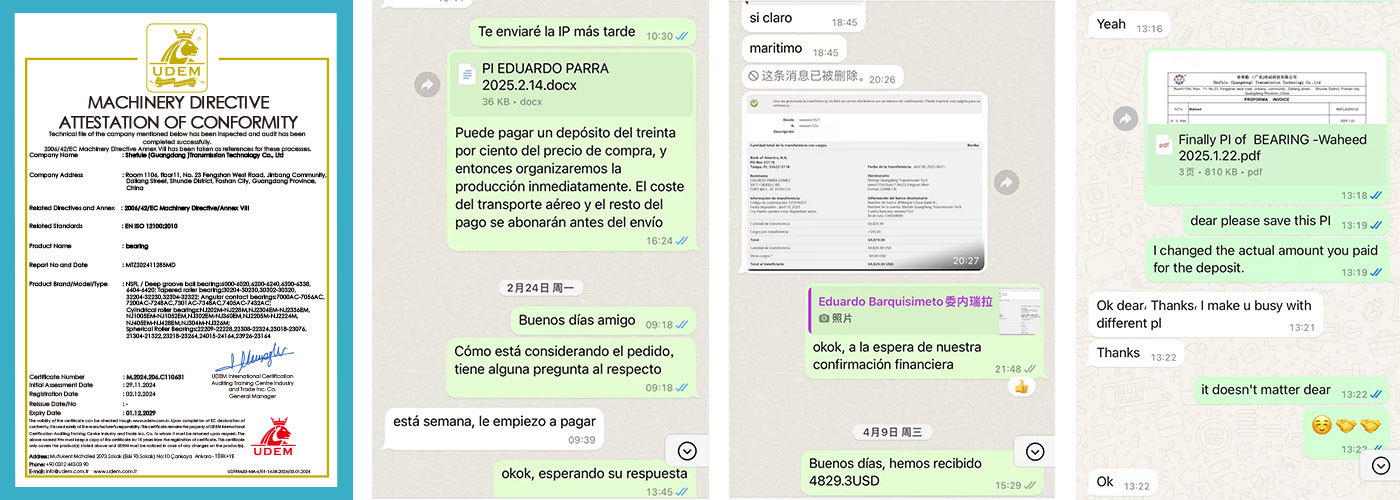

CUSTOMER CHAT

APPLICATION AREAS

We provide you with customized solutions for your industry.

CONTACT US

Provide you with free samples and quotes.

RELATED PRODUCTS

Experience the difference that our expertise and dedication can make for your business.

10% DISCOUNT FOR NEW CUSTOMERS

WhatsApp:+8613211157555

Tel: +8613211157555

Address:Room 1106, 11th Floor, No. 23, Fengshan West Road, Jinbang Community, Daliang Street, Shunde District, Foshan City, Guangdong Province

Copyright 2025 Schaeffler (Guangdong) Transmission Technology Co., Ltd. SEO Business license